EMI Shielding Film with Good Shielding

EMI Shielding Film with Good Shielding

Product Description

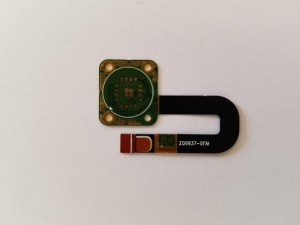

EMI Shielding Film is mainly used in FPC which consist of Modules for mobile phones,PC,medical devices,digital cameras,automotive instruments,etc.

Product Availability

LKES-800

LKES-1000

LEKS-6000

Product Features

(1) Good processing characteristics

(2) Good electrical conductivity

(3) Good shielding properties

(4) Good heat resistance

(5) Environmental friendly (Halogen free, meet requirements of RoHS Directives and REACH, etc.)

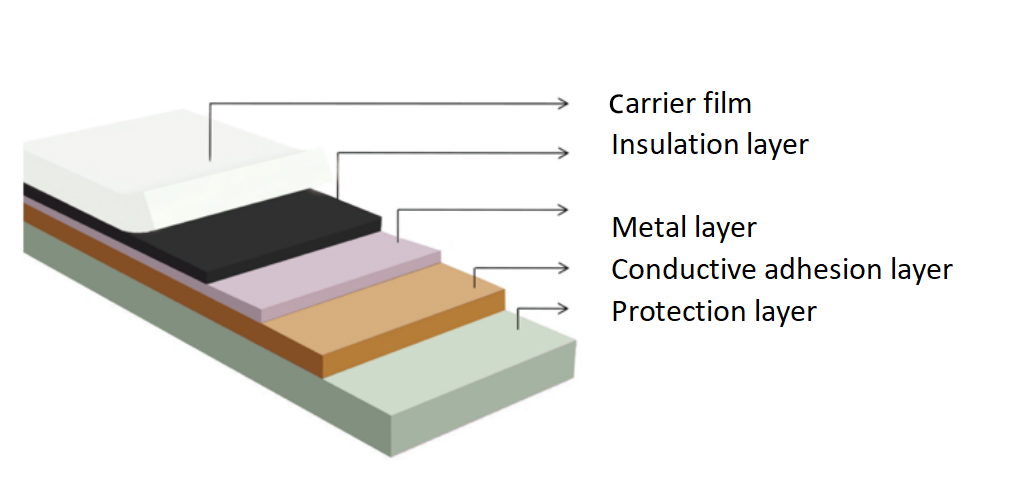

Product Structure

Product Characteristics

LKES -800

| Item | Test Data | Test standard or Test method |

| Thickness (Before Lamination,mm) | 16±10% | Enterprise Standard |

| Thickness (After Lamination,mm) | 13±10% | Enterprise Standard |

| Ground Resistance(Gold plated,Phi1.0mm, 1.0cm,Oh) | HE C5016 1994-7.1 | |

| Peeling strength of reinforced film (N/25mm) | Enterprise Standard | |

| Lead-free Soldering Reflow (MAX 265℃) | No stratification; No foaming | HE C6471 1995-9.3 |

| Solder (288℃, 10s, 3 times) | No stratification; No foaming | HE C6471 1995-9.3 |

| Shielding Properties(dB) | >50 | GB/T 30142-2013 |

| Surface Resistance(mOh/□) | <350 | Four Terminal Method |

| Flame Retardant | VTM-0 | UL94 |

| Printing Character | PASS | JIS K5600 |

| Glossiness(60°, Gs) | <20 | GB9754-88 |

| Chemical resistance(Acid,alkali and OSP) | PASS | HE C6471 1995-9.2 |

| Adhesion to Stiffener (N/cm) | >4 | IPC-TM-650 2.4.9 |

LKES-1000

| Item | Test Data | Test standard or Test method |

| Thickness (After Lamination,mm) | 14-18 | Enterprise Standard |

| Shielding Properties(dB) | ≥50 | GB/T 30142-2013 |

| Surface Insulation | ≥200 | Enterprise Standard |

| Adhesive Fastness(Hundred cells test) | No cell fall off | JIS C 6471 1995-8.1 |

| Resistant to Alcohol Wipe | 50 Times no damage | Enterprise Standard |

| Scratch Resistance | 5 times no Leakage of metal | Enterprise Standard |

| Ground Resistance, (Gold plating,Phi1.0mm, 1.0cm,Oh) | ≤1.0 | HE C5016 1994-7.1 |

| Lead-free Soldering Reflow (MAX 265℃) | No stratification; No foaming | HE C6471 1995-9.3 |

| Solder (288℃, 10s, 3 times) | No stratification; No foaming | HE C6471 1995-9.3 |

| Printing Character | PASS | JIS K5600 |

LKES-6000

| Item | Test Data | Test standard or Test method |

| Thickness (After Lamination,mm) | 13±10% | Enterprise Standard |

| Shielding Properties(dB) | ≥50 | GB/T 30142-2013 |

| Ground Resistance, (Gold plated,Phi1.0mm, 1.0cm,Oh) | ≤0.5 | HE C5016 1994-7.1 |

| Ground Resistance, (Gold plated,Phi1.0mm, 3.0cm,Oh) | 0.20 | HE C5016 1994-7.1 |

| Release force (N/cm) | Enterprise Standard | |

| Surface Insulation(mOh) | ≥200 | Enterprise Standard |

| Adhesive Fastness(Hundred cell test) | No cell fall off | JIS C 6471 1995-8.1 |

| Lead-free Soldering Reflow (MAX 265℃) | No stratification; No foaming | HE C6471 1995-9.3 |

| Solder (288℃, 10s, 3 times) | No stratification; No foaming | HE C6471 1995-9.3 |

| Flame Retardant | VTM-0 | UL94 |

| Printing Character | PASS | JIS K5600 |

Recommended Processing Condition

| Lamination Method | Lamination condition | Solidification condition | |||

| Temperature(℃) | Pressure(kg) | Time (s) | Temperature (℃) | hour(min) | |

| Quick- Lamination | LKES800/6000:180±10LKES1000:175±5 | 100-120 | 80-120 | 160±10 | 30-60 |

Note:Customer can adjust the technology based on the real condition when processing.

(1)Peel off protection layer first, and then bond to FPC, 80℃Heating table can be used for pre bonding.

(2)Laminate in accordance with the above process, take out, and then peel off the carrier film after cooling.

(3)Solidification process.

Packing

(1) Standard Specification of product: 250mm×100m.

(2)After removing static electricity, the products are packed in aluminum foil paper and also put drier in it.

(3) Outside is packed in paper cartons and fixed to ensure the safety of products during transportation and handling, and avoid damage.

Storage and Attention

(1)Recommended Storage Condition

Temperature: (0-10)℃; Humidity: below 70%RH

(2)Attention

(2.1)Please do not open the outside package and balance the shielding film at room temperature for 6 hours before using to reduce the effect of frost and dew on the shielding film.

(2.2)Suggest to be used as soon as possible after take out from the cold storage, in case of quality changing under the normal temperature for long time .

(2.3) This product is not resistant to water phase sealing agent and flux, if having the above processing technology, please test and confirm first.

(2.4) Suggest quick lamination, vacuum laminating needs to be tested and confirmed.

(2.5)Quality guarantee period under the above condition is 6 months.